2021/09/14

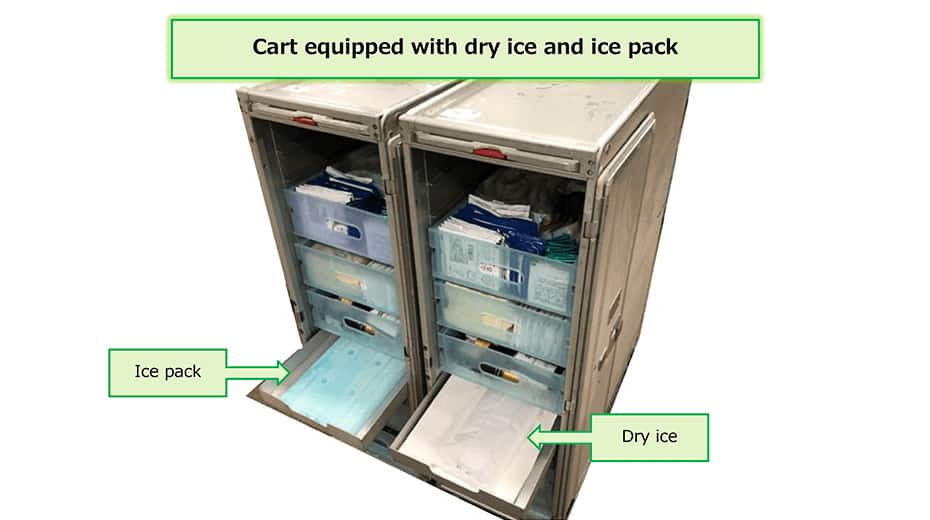

From September 20, 2021, reusable ice pack will be introduced to keep in-flight meals and beverages cold on ANA Group domestic flights.

Dry ice to be eliminated from domestic flights

ANA Group has been using dry ice to keep in-flight meals and beverages served to customers cold for quality control purposes. While dry ice has a very high cooling capacity and is disposable and easy to operate, it has the problem of CO2 emissions due to sublimation and increasing cost. Also, due to the extremely low temperature of -78.5 degrees Celsius, we had to be very careful when handling it. By switching to reusable ice pack and reducing the annual use of dry ice by 1,700 tons (FY 2019 actual), we can reduce the 1,700 tons of CO2* emissions that occurs from the sublimation of dry ice.

- * Dry ice is produced by applying high pressure to CO2.

In addition, the repeated use of ice pack will result in an annual reduction of about 30 tons of dry ice packaging materials and matting placed under the dry ice, and is expected to reduce total costs by approximately 200 million yen per year (approximately 80% reduction) compared to dry ice. Also, by switching to ice pack, the catering staffs and cabin attendants can concentrate on their work without worrying about being exposed to dry ice.

Conducted a number of demonstration tests

Even though it is environmentally friendly and reduces costs, it is important to maintain the quality of the in-flight meals and beverages served to customers. In order to resolve this concern, we began selecting materials about a year and a half ago, and conducted a series of verifications on the ground and on flights to thoroughly check whether the materials could keep in-flight meals and beverages cold for a certain period of time. The ice pack to be introduced this time is made of food additives that are harmless to human contact, to ensure safety, and can keep in-flight meals and beverages at a stable temperature.

Interview with the person in charge

We interviewed the person in charge, Mr. Nakatani (from Products & Services Planning, Customer Experience Management & Planning), about the background of the introduction and verification of the ice pack.

Please tell us about your daily work.

I am in charge of planning the in-flight service, and I am involved in all matters related to the in-flight service, such as deciding on the content and procedures of the service, the menu for in-flight meals and drinks, and selecting the items to be used on board.

What was the reason for switching to ice pack?

To promote in-flight resource recycling, the first step was to identify plastic materials and disposable items. Among them, dry ice, which was carried on all flights, was very prominent due to the large amount of material. We had been relying on the cooling capacity of dry ice as a standard, and we had not been able to start examining it, but when we heard about the technological advances in ice pack, we started to investigate and research. Through our research, we found out that ice pack is a reusable product that does not waste limited resources, can reduce CO2 emissions from the ANA Group, and can significantly reduce costs compared to dry ice. We were able to create a positive image in all aspects, including other side effects, which led us to launch a project to introduce refrigerants.

How and what did you focus on in the verification process?

The first hurdle was to find ice pack with the same potential as dry ice in order to maintain the quality and satisfy the customers. First, we placed more than 10 carts filled with dry ice and ice pack in a conference room under the sun, and periodically opened and closed the cart doors from morning to night to check the temperature changes. We found that dry ice and ice pack have different characteristics. In contrast to dry ice, which initially showed a high cooling capacity and maintained it, the ice pack showed a long-lasting cooling effect at a stable temperature. For beverages and in-flight meals that do not need to be frozen, the temperature range of the ice pack has been found to be sufficient to keep them cool without using the ultra-low cooling power of dry ice. It's not like freezing ice cream, so I thought, "This could work ". Focusing on the characteristics, we spent a lot of time to understand the character and capability of the ice pack by verifying it in various cases to find out how long it lasts, what kind of environment it is strong or weak in, and what the appropriate volume of the ice pack is.

What was the most difficult part of the project?

The drinks in the carts are placed on the carts when the cabin attendants are serving drinks, and the length of time the cart doors are kept open varies from flight to flight, so we had to go through a lot of trial and error while flying many times between Haneda and Okinawa to see how far we could go to verify that the quality was maintained. As we repeated the verification process, the data became available and the hypothesis became more certain, but I would say that the long period of verification before that was a difficult period.

How would you like to contribute to resource recycling in the future?

If the quality produced by our in-flight efforts, such as resource recycling, CO2 emission reduction, and de-plasticization, is equal to or better than the conventional quality, or within an acceptable range, then we would like to have the courage to make a choice that is closer to the environment. Of course, in order to do this, we need to understand the values of our customers and the needs of society, so I would like to keep studying and finding out what's going on in the world. However, I believe that a sustainable society in the true sense of the word will not be realized if companies lose their strength by promoting environmentally friendly initiatives. One by one, we hope to realize initiatives that are both environmentally friendly and economically sustainable.

The ANA Group will continue to strive to provide even more environmentally friendly products and services.