2024/07/30

ANA MOTOR SERVICE CO.,LTD. (ANAMS) has upcycled a belt loader*1 used in airports and targeted for scrapping into an EV*2 vehicle from a diesel engine.

The conversion of aircraft ground support equipment to EVs, which will be revitalized into new vehicle models using the latest technology, is the first initiative of its kind in the Japanese airline group.

- *1 Vehicles for loading baggage onto aircraft

- *2 Powered by electricity

Upcycling based on technical capabilities

In addition to belt loaders, airports have many other special vehicles that are used around aircraft, such as aircraft towing vehicles, passenger step vehicles, and snowplows, which are called aircraft ground support equipment (hereinafter GSE).

ANAMS is a company that plays a wide range of roles in these GSEs and passenger boarding bridges (PBBs), including servicing, maintenance, design, and even sales.

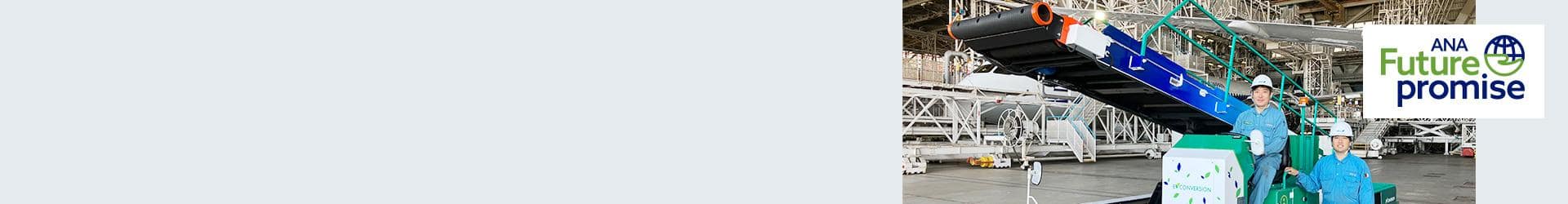

At the initiative of an employee of ANAMS, an engineering group that is the pride of the ANA Group, a belt loader that had been used for 29 years and was to be disposed of was designed for structural modification, assembled the electric circuit, and installed a special battery, motor, and reduction gear for EV use, all of which were carried out in-house.

ANA Group's decarbonization initiatives outside of aircraft operations

The ANA Group has set a medium-term environmental goal of "reducing CO2 emissions generated outside of aircraft operations by 33% or more by FY2030 (compared to FY 2019)," and the conversion of GSE to EVs is one of the essential elements for achieving this goal.

The conversion of the belt loader to an EV will provide an option to revive the old GSE, other than purchasing a new EV vehicle, and is expected to make a significant contribution to the ANA Group's decarbonization efforts.

Operation is scheduled to begin at Tokyo International Airport by the summer of 2024.

Interviews with project members

We interviewed Mr. Kogure and Mr. Uchino of the ANAMS GSE Maintenance Department, who are usually in charge of GSE maintenance and are project members of the belt loader EV conversion.

What made you decide to convert the belt loader to an EV?

(Mr. Kogure) This project was launched in the hope that ANAMS could do something to achieve the goal of decarbonization by the year 2030. Although we have been purchasing EVs at the time of vehicle renewal, there was a sense of urgency that this alone would not be enough to achieve our mid-term environmental targets in time. We also felt that it would be wasteful to dispose of the vehicles while they were still usable.

What was the most difficult/unforgettable experience from development to introduction?

(Mr. Kogure) I was in charge of the project, which took two years from conception to completion, and was responsible for checking the progress of the work and the existence of any defects. Since I was mainly repairing GSEs in my regular work, this was the first time for me to build a vehicle from scratch. While removing and replacing the entire engine and wiring of a vehicle that had previously been equipped with a diesel engine, writing a wiring diagram from scratch was a new challenge. Wiring is everything in an EV vehicle, so drawing this wiring diagram was the most time-consuming part. I am very happy that it turned out exactly as I had envisioned.

(Mr. Uchino) Since the date of the in-house presentation had been set in advance, we planned and worked to have it ready by that date, but due to various hurdles, we just barely completed it the day before. From there, we repaired it and I will never forget how impressed I was when it first started working. Also, since a very large number of parts are used in the EV, purchasing and managing those parts was very difficult, and we had a lot of discussions with the members about the placement of parts, which I believe resulted in a satisfactory finish.

Are there any particular points?

(Mr. Uchino) We worked while considering that the operator who actually controls the vehicle should not be overburdened. We made sure that the operation of the vehicle and the accelerator pedal were the same as those of a diesel-powered vehicle when transporting cargo.

We were also particular about making improvements without changing the shape from the original vehicle. It was very difficult to fit the parts into the existing vehicle because the sizes of the parts to be installed were fixed.

Since the concept is the same as that of the ANA Future Promise Jet&Prop operated by the ANA Group, the vehicle's design uses the same "water and green" motif as the airframe.

I can't wait to see the converted EV belt loader loading cargo onto the ANA Future Promise Jet & Prop.

Is there anything you would like to challenge in the future?

(Mr. Kogure) As we consider converting the second and third vehicles in the future, we were able to find many issues to be addressed in this project. Our challenge for the future is to clear these issues and accumulate knowledge and techniques while making the product even more efficient and high quality.

The ANA Group will continue to promote decarbonization initiatives outside of aircraft operations.