2023/04/27

Aprons made from maintenance work clothes

A store in Yaesu*1, Tokyo called "Tochi-Dochi", owned and operated by the ANA Group which opened in January 2023, sells locally produced goods that can only be found in the region throughout Japan. To make it easily recognizable that the store is owned by the ANA Group, the sales staff at Tochi-Dochi have adopted aprons remade from ANA maintenance work clothes as their store uniforms. Taking a cue from the hugely successful upcycled ANA maintenance work clothes bags, Ms. Uno of ANA Akindo came up with the idea of creating and using aprons from discarded maintenance work clothes as uniforms for sales staff, and even sewed and produced 18 of them herself. The aprons have become popular and received requests from customers to commercialize them, and now the product has been commercialized.

-

*1.The first store, at Seijogakuenmae, has already closed on March 31, 2023.

Features of the commercialized aprons

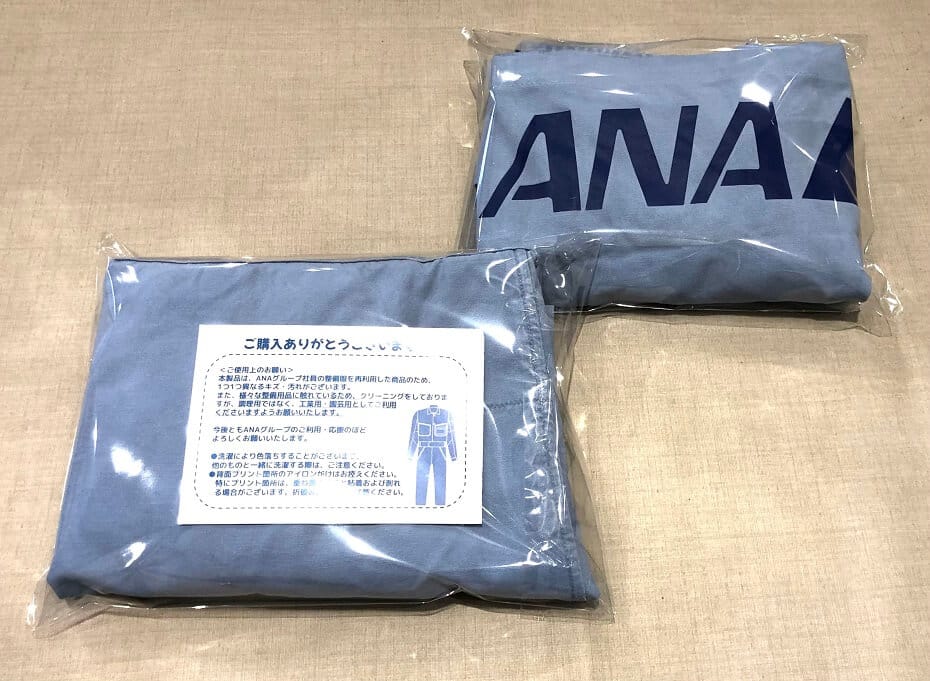

Maintenance work clothes, of which more than 300 are disposed annually, will be reborn as aprons with new value. The commercialized aprons are designed with reference to the aprons for sales staff made by Ms. Uno. They are manufactured by Fujisey Corporation, and sold on the MRO aircraft factory tour (in Okinawa). Thank you cards accompanying the aprons are made of paper, each of which is handmade with care by ANA Aoshima Factory.

Each apron is an upcycled product, so the color, texture, size, etc. will vary one by one. In addition, since they are exposed to various maintenance products, we clean them, but we encourage you to use them for industrial and gardening use.

Thoughts of the person in charge

We interviewed Ms. Masumi Uno of ANA Akindo, the person in charge of this project.

What were some of the challenges you faced in the process of commercializing the maintenance clothes aprons?

This was our first attempt, from procuring materials to deciding on a manufacturing company, and we had many concerns and worries about what kind of aprons would be produced due to the different sizes and stains of each piece, and whether they would be of high enough quality to be sold.

In addition, because we were using discarded fabrics instead of manufacturing new fabrics, we could not predict how much we would be able to secure, and all the process took half a year later than planned. However, all the people in charge of the manufacturing and coordinating companies who cooperated with us were very cooperative and helpful.

Since we have just started the manufacturing and sales business, there are still many issues to be addressed, such as sales locations and sales volume, but we will do our best to please all ANA fans.

Please tell us about your thoughts on these aprons.

As a cost-saving measure after the spread of COVID-19, I had been manufacturing these aprons for the sales staff on a home sewing machine, not expecting that they would be commercialized.

The manufacturers who cooperated with us in the production and sales of the aprons also took a strong interest in the SDGs and were proactive in their efforts, including proposing the development of other products in addition to the reusable aprons. We hope to continue our resource-conscious activities in the future, such as product development using leftover materials from the reused aprons.

The ANA Group will continue to strive for the effective use of limited resources while valuing the awareness of each and every employee.